Inside the World of Smart Materials

Hold up your hand. Take a look at your pointer finger. Now angle your finger down so that the pad of your fingertip touches the bottom of your finger. This simple movement—made possible by the bendy parts—may not seem like much, but to people like SPIE Senior Member Zoubeida Ounaies and Intel engineer Saad Ahmed, it opens up a world of sensing and operating possibilities.

"We look for inspiration in a variety of places," says Professor of Mechanical Engineering Ounaies, whose Electroactive Materials Characterization Lab (EMCLab) at Penn State develops smart materials that enable actuation and sensing. Ahmed, in fact, came up with the idea of mimicking the structure of a human finger in a polymer actuator while he was a student in Ounaies' lab. This year, in a presentation at SPIE Smart Structures + Nondestructive Evaluation, he described wanting to improve the current state-of-the-art robotic grippers when it comes to reaction time, force, stress, and functionality. He remains intrigued by what segmented actuation—copying the bending action of a human finger—could accomplish.

From biomimicry to boxes

When it comes to inspiration, however, biomimicry isn't the sole muse. Ounaies, who is taking on the role of Symposium Chair of SPIE Smart Structures + Nondestructive Evaluation next year, says that grants from the National Science Foundation EFRI (Emerging Frontiers in Research and Innovation) and the Air Force Office of Scientific Research supported her team's pursuit of origami-inspired materials and systems research. Similar to Ahmed's vision of the fingerlike robotic gripper, origami-inspired actuators use a cleverly-configured smart polymers for controlled folding and unfolding capabilities. While a few research groups were similarly funded in the area of origami-inspired design, what makes the Ounaies lab's efforts unique was the use of smart materials to fold and unfold the structure on demand.

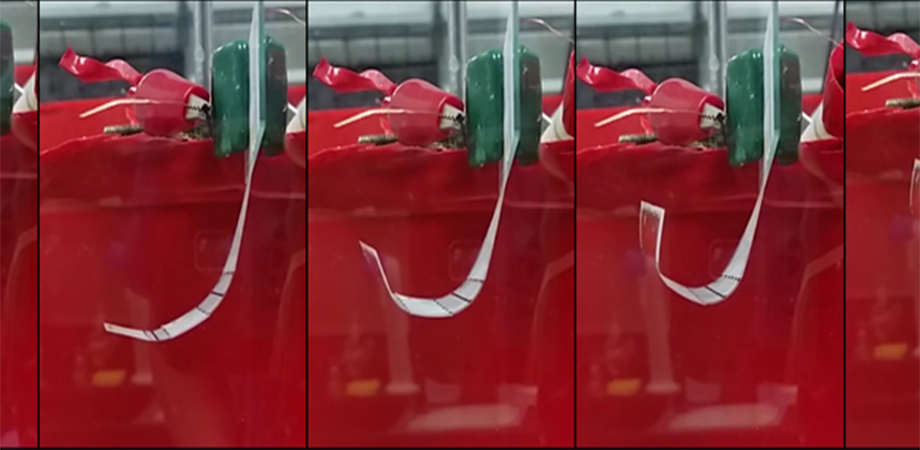

Robotic grippers in Ounaies' lab were inspired by the notches in a human finger. Credit: S. Ahmed, et al. doi.org/10.1117/12.2514902.

"There is a big difference between bending and folding," she explains. "Materials which can bend, due to an electrical or magnetic external force, are common in smart polymers. Materials that fold due to an external force, however, are less common. The ability for a material to fold on demand and over and over again without wearing out is an ideal scenario."

She uses the idea of a smart materials box—made of polymers or polymer-based composites—as an example. The box is a 3D structure, she says. Imagine that you move to a new home, unpack the box, and now need to store it using limited space. So you apply an external force, electric or magnetic, to it, and the box recognizes it has pre-set folds in its material. The external force actuates the folds, and the box becomes flat. Now, say you need to use the box again: you apply the opposite force—if you started with electric, now you'd use magnetic—and it springs back into its original 3D shape. On an individual scale it may seem impractical to use smart-material boxes, but imagine an industrial, high-volume manufacturing facility and you begin to see the real impact smart materials can have in regards to efficiency.

Space-saving packing material is just one potential application of this technology, says Ounaies, noting exciting possibilities in aerospace and medicine. But while Ounaies says she occasionally looks at her research from a practical and translational standpoint, "what teases my brain, and what I'm more passionate about, is the basic science-driven research."

People power

It may seem like Ounaies, with her curious mind, was destined for the creative world of smart materials. While she did obtain her Master of Science in mechanical engineering and her PhD in engineering science and mechanics, she began her studies in the mathematical world of computational fluid dynamics—until, that is, a classmate dragged her to a lecture at Penn State on ferroelectric materials by Professor Eric Cross.

"It was fascinating," she says of her immediate captivation with the idea of responsive and smart materials. "Afterwards I said, ‘I'm getting my PhD in that, whatever that is!' That's how it all started." The classes she took with Cross had a long-lasting impact in more ways than one: in 2017, Ounaies gave a eulogy for Cross at the SPIE Smart Structures conference.

Ounaies has always appreciated the strong sense of community she discovered within the smart-materials field, such as at the SPIE Smart Structures + Nondestructive Evaluation conferences. "It's all about the people, truly," she says. "Often, when I was a graduate student, I would meet someone at a networking event and look at their badge and go, ‘Oh my God! I just read their paper!' It was like our own version of celebrities-science celebrities! It was pretty awesome."

Now she strives to maintain a tight-knit community in her own lab. Whether it's through team-building exercises, dinners, group outings, or lunch celebrations—she admits that food is a core theme—she acknowledges the accomplishments of her students, big and small. "I always try to treat each of my students as the whole person that they are, not just the scientist. I also try to balance diversity in my group: I joke that I want my team to be like the UN—a range of people from different countries, cultures, backgrounds. It's so important to celebrate our differences." Once a semester, this commitment comes to delicious fruition: a team potluck to which everyone brings or cooks their favorite home-country dish.

The EMCLab Group at Penn State. Credit: Zoubeida Ounaies.

Organic collaboration

Diversity is important to Ounaies not only within her lab, but in her research collaborations as well. She values an interdisciplinary approach and her favorite research interest has involved three institutions over the years.

The Cellulose Project, as Ounaies referred to it, is a collaborative effort between her lab, Penn State's Chemical Engineering and Materials Science Department, Inha University in Korea, and University Cadi Ayyad in Morocco. These researchers are working together to address an age-old question in the naturally-occurring materials community: is cellulose piezoelectric in its natural state, and, if so, to what extent?

"The research community has been looking at cellulose for a long time," explains Ounaies. Cellulose, the organic compound known to be one of the most abundant on Earth, could have a dramatic impact on the renewable energy front if researchers learn to exploit it properly.

"They say ‘It should be piezoelectric in its natural state because of its chemical structure', but the piezoelectricity within cellulose appeared to be very low; for a long time it couldn't even be measured." With the improvement of measurement instrumentation over the years, researchers can now definitively say that cellulose is piezoelectric; however, exploiting its piezoelectricity at an engineering scale is still an issue.

Ounaies explains, "When you extract cellulose from plants, for example, the process destroys the order of the chemical structure that gives it its piezoelectricity. How can we preserve that structure during extraction, so we can measure it and use it to make sensors and actuators?"

The first step for Ounaies and her many collaborators is getting back to basics. "We are working to better understand cellulose," she says. "We are answering a lot of ‘Why is this not working?' type-questions in order to answer the question ‘Well, how do we get it to work?'" In trying to answer the basic, building-block questions that Ounaies is passionate about, the team learned that cellulose extracted from animals has a different structure than cellulose extracted from plants. In fact, cellulose in animals may have a higher polarity, which makes it more viable for use in smart devices.

With exciting finds like this it becomes apparent that diverse groups of researchers with high levels of inquisitiveness and energy—chemical engineers focusing on extraction methodologies and materials engineers such as Ounaies, who are measuring and applying the generated electricity to develop smart devices—make for the most innovative collaborations. "Together, we offer a range of expertise that's really exciting," she says. "It takes the world," she smiles, "not just a village."

| Enjoy this article? Get similar news in your inbox |

|