Photons go to extremes

The only way to really learn what happens at the extremes is to go to the extremes. For adventuresome types, such as extreme athletes and explorers, that means scaling forbidding mountains, diving to unimaginable ocean depths, or pushing vehicles to ever greater speeds, at great expense and even greater danger.

Scientists and engineers looking to understand the behavior of a material or chemical compound under extreme conditions don't have to risk life and limb, of course. But the challenges they confront can be no less daunting. What if you want to study the conditions that exist at the center of the Earth, in the atmospheric depths of Jupiter, or even just what's going on at the phase transition when a metal begins to melt? Even the most sophisticated mathematical models can't beat actually seeing it as it happens. Fortunately, scientifically at least, it's not always necessary to go directly to the source. Some extreme conditions can be recreated in the laboratory, where they can be studied in detail and in safety.

Intro to shock compression

Everyone knows that x-rays can provide a window into structures, whether by casting the shadows of bones or refracting off the intricate frameworks of atomic and molecular lattices. But when precisely tuned and controlled at high energies, they can also provide an exquisitely fine look at dynamic processes happening at extremely short timescales. Creating powerful x-rays tailored to specific experimental parameters requires a synchrotron, which can produce and accelerate electrons and protons to relativistic speeds, and then manipulate them in various ways for use by experimenters.

Such capabilities allow researchers a window into "a whole menagerie of stuff," says Washington State University's John Sethian. "You can explore states of matter that have never been explored or accessed before. You can look at bonds breaking, for example, or you can look at how materials respond differently to varying pressures. You can measure the pressures under which a material melts at rapid compression. You can look at how water freezes, you can look at how diamond makes a transition. Just discovering the pressure, a very precise measurement of where something melts under dynamic compression, is a major step forward."

To access those kind of extreme conditions, scientists are combining sophisticated synchrotron light facilities with a decades-old experimental physics tool called shock compression. As the term implies, shock compression concerns the response of materials when subjected to high impacts or compression of very short duration.

Anyone who's ever hit their thumb with a hammer, dropped a drinking glass, or set off a firecracker is quite familiar with the effects of such phenomena on the macroscale. But at the microscale, shock compression creates many other important consequences, such as causing temporary or permanent deformations, inducing phase transitions, and greatly increasing temperature, all of which can provide invaluable information both about the structure of a material and how it responds to stress. "If you want the most extreme thermophysical conditions in the laboratory, the only game in town is shockwave compression," says Washington State University condensed matter physicist Yogendra Gupta, principal investigator at the Dynamic Compression Sector (DCS) of the Advanced Photon Source (APS) at Argonne National Laboratory, in the western suburbs of Chicago.

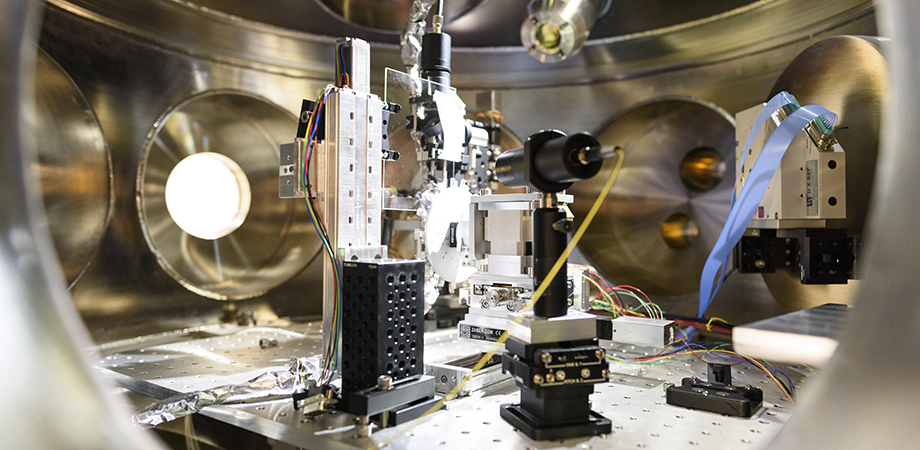

The 100-J ultraviolet Nd:glass system at the Dynamic Compression Sector Laser Shock Facility, Advanced Photon Source, Argonne National Laboratory. Credit: Hubner/Washington State University

Gupta is interested in what happens to structures at the level of molecules and atoms when subjected to shock. "The analogy I give is, it's a bit like an astrophysicist studying the Big Bang," he says. "But that happened billions of years ago, and we're now looking at the remains of it. My joke is that I like to study little bangs, but do them in real time, not after the fact." To do that, Gupta and his colleagues use the precisely tunable and extremely powerful x-ray beams produced by the third-generation APS synchrotron to probe a vast range of phenomena, including structural changes in materials under extreme conditions, deformation effects, and even chemical reactions—all in situ and in real time.

Shock compression research began in earnest during World War II, mostly centered in the Manhattan Project, as the builders of the first atomic bomb sought to figure out how to compress a sphere of plutonium into a supercritical mass. After the war, shockwave experiments continued, not only to develop new weapons but also to study other phenomena. Many were highly classified, performed as part of the hundreds of atomic bomb tests conducted during the Cold War, because a nuclear explosion was the only way to generate the extreme pressures and temperatures required.

Those experiments were definitely extreme, not to mention massive in scale and hazard, and came to an end with the abolition of nuclear weapons testing. Shockwave experiments continued, however, using considerably more peaceful techniques such as firing projectiles or hitting sample materials with bursts of highly pressurized gas. But in all these methods, most of the resulting data still had to be examined after the fact. It still wasn't possible to study phenomena dynamically, in the moment, in real time. Nor was it possible to see what was happening beneath the surface, because only optical observations were available.

"Optical physics is based on wavelengths down to the ultraviolet, between 300 nanometers to maybe 800 nanometers. That's what the human eye can see," explains Gupta. "What you can interrogate depends on the wavelength of your photons. Optical photons between 300 and 900 nanometers can't look inside nontransparent objects. And the length scales you can study are limited to these sort of length scales. If you want to look at length scales smaller than half a micron, then you've got to start doing x-rays."

Looking deeper and at faster timescales required the development of new tools that can harness photons of different wavelengths and energies, such as the x-ray synchrotron. Researchers such as Gupta are using photons in new and synergistic ways, combining the penetrating ability of x-rays to see in ways far beyond the capabilities of visible photons deep beyond the surface of a material, while other photons marching in lockstep in the coherent light of a laser can deliver a burst of energy to induce a fast and powerful shockwave.

"The APS x-ray source synchrotron is like an x-ray strobe light, and each flash of the strobe is about 90 picoseconds [90 trillionths of a second]," explains Gupta. "And you've got multiple flashes separated by hundreds of nanoseconds. And that is almost ideal, because shock experiments range anywhere from a few nanoseconds to about a microsecond. If you want to measure things within that timescale, you need temporal resolution of your source in that same timescale."

As might be expected for laser shock studies, the laser beam is also a vitally important part of the equation. The Dynamic Compression Sector (DCS) at the APS features a laser shock station that houses an ultraprecise 100 joule, Nd:glass laser with a pulse duration of 5-17 nanoseconds and a wavelength of 351 nanometers, designed and built by the University of Rochester Laboratory for Laser Energetics and LOGOS Technologies.

Photons, of course, possess momentum which can exert a faint pressure on matter, but in a laser shock experiment, they're not actually what directly delivers the shock. The surface of the sample to be subjected to shock is coated with a thin ablative layer of a different material facing the direction of the laser beam. "The laser deposits all its energy on the ablator," Sethian explains. "Because the laser is so intense and has such a short pulse, it turns the front (laser side) of the ablator into a plasma. That plasma expands rapidly away from the sample, and by conservation of momentum, applies a pressure to the sample, which is what generates the shock. So you create a shock that goes through the material, and that shockwave alters the structure of the material on a very fast timescale and at very short lengths. And then you use any one of a number of diagnostics to figure out what's going on."

A quality that Sethian calls the "smoothness" of the laser is crucial for this kind of work, and the beam at the DCS Laser Shock Station is designed to deliver the ultimate in smoothness, making it a rather unique tool. "If you look across the face of the laser beam, there's probably 7-8 percent variation in the peak to valley across the beam. That's extremely important because if you're looking perpendicular to the laser beam at the target being compressed, you want to make sure what you're seeing is the compression wave due to the entire laser. If the laser is nonuniform, which means it has peaks and valleys, you're not sure what you're looking at is due to a peak or a valley or something in between. So this gives you a very accurate representation and picture what's going on."

The DCS laser shock station has already produced some substantial results since it was declared fully operational in 2019. The initial experiments determined the exact melting pressure of tantalum, an important metal used in electronics. More recently, laser shock studies at the APS have revealed the microstructural changes undergone by iron at its melting point under high pressures inside planetary cores, and the existence of a phase transition occurring in gold just before its melting point. "No one had seen (or guessed) at that," Sethian notes.

Understanding additive manfacturing at the nanoscale

The combination of high-energy x-ray imaging and lasers is also spurring developments in the cutting-edge fabrication techniques of additive manufacturing (AM), more commonly known as 3D printing, some of which also use laser technologies. Understanding what's actually happening on the nanoscopic scale of an AM component as it's created has proven a major challenge. That incomplete understanding forces scientists to rely on indirect modeling based on other only partly comparable industrial techniques, such as welding. This apples-to-oranges approach leads to imperfect control of the AM process and the production of defect-laden parts that might not meet desired standards.

Aiden Alexander Martin, who studies metal additive manufacturing at the Lawrence Livermore National Laboratory, doesn't use laser shock experiments, but the unique capabilities of x-ray synchrotron imaging on their own are indispensable for his particular work. Laser-based AM techniques such as laser powder bed fusion, for example, which uses a laser to melt powdered material into solid parts, are extremely complex and fast-moving, involving high temperatures, laser-metal interactions, molten metal flow, quick phase transitions, vaporization, and other phenomena—all of which can affect the strength and integrity of the finished piece, and all opaque to optical observation.

X-ray sources at the APS reveal small pore defects, which are created during laser powder bed AM, specifically when the laser reaches the end of a track and turns. Credit: Aiden Martin/Nature Communications

"You can imagine a laser hitting a surface and melting and cooling," says Martin. "It's happening very fast. We need x-ray sources like the APS to actually probe those kinds of timescales. And the reason we use x-rays compared to say optical measurement, is the x-rays can probe within the metal structure. At APS, we take images where we can actually see the liquid metal under the surface, and we can see it moving. We can see pore formation and other phenomena that either cause defects in the part, or change the material stress and strength properties."

With data in hand showing basic processes of AM fabrication of different metals and different parts, detailed simulation models can be constructed and validated, then used to refine AM techniques and design further experiments to address unanswered questions.

At the extremes of temperature, pressure, and stress

Although the advanced photon source at Argonne currently holds a unique position as the brightest (i.e., highest concentration of photons) x-ray source in the western hemisphere, it's not the only facility where such research is done. Other synchrotron light sources in North America include the National Synchrotron Light Source at Brookhaven National Laboratory in New York, Stanford's SLAC National Accelerator Laboratory and Berkeley's Advanced Light Source in California, along with various smaller facilities elsewhere. Internationally, notable facilities are the Diamond Light Source in the United Kingdom, the European Synchrotron Radiation Facility in France, and KEK in Japan.

At all these facilities, scientists are using synchrotron light to probe the structure of matter, not only under normal conditions but at the very extremes of temperature, pressure, and stress. Whether investigators are using the short, sharp shock supplied by a laser, or a hurtling gas-propelled projectile, or just the unprecedented capabilities provided by the state-of-the-art synchrotron light facilities now available, they're not just answering old questions but finding new ones to ask that weren't even previously imagined. And in some cases, says Sethian, "They've actually even contradicted previous data in which people didn't have this accurate a laser or x-ray source."

Maybe not as "extreme" as climbing Everest or diving the Marianas Trench, but scientifically speaking, these achievements are pretty impressive for a bunch of photons.

Mark Wolverton is a freelance science writer and author based in Philadelphia.

| Enjoy this article? Get similar news in your inbox |

|