Ahead of the curve: an optical fiber sensor for measuring deviations in the spine

The backbone or spine (or the vertebral column) can be divided into four major curves. The shapes of these curves allow our bodies to properly distribute weight in different positions and conditions, such as when sitting or bending down. However, certain spine malformations can cause these curves to deviate significantly, which may lead to chronic pain or serious disabilities.

As a result, doctors need to properly measure the curvature of these spine curves to diagnose potentially harmful conditions at an early stage. The traditional way of doing this is to take X-ray images of the patient’s spine and calculate the curvature of each section, either manually or using an image analysis software. Unfortunately, this approach has some downsides: it is time-consuming and prone to both human and machine error. Moreover, X-ray radiation is harmful to our bodies, so it’s best to keep radiographic exams to a minimum.

Taking note of this issue, researchers have delved into different types of systems and sensors to measure spine curvature. These alternative techniques are varied, involving motion capture systems like Vicon and Kinect, inertial sensors, or optical sensors. However, they share a common limitation: they cannot provide accurate quantitative measurements essential for doctors to diagnose problems in spine curvature.

To address this problem, researchers from the University of Tabriz in Iran developed a new type of sensor based on optical fibers. As explained in their paper published in SPIE’s Optical Engineering, optical fiber sensors offer many advantages, including low cost, high sensitivity, and small size. These sensors have already been used to monitor the curvature of structures and robotic arms. But measuring both the magnitude and direction of the spine’s curvature presents an additional challenge—one that the team overcame through innovative design.

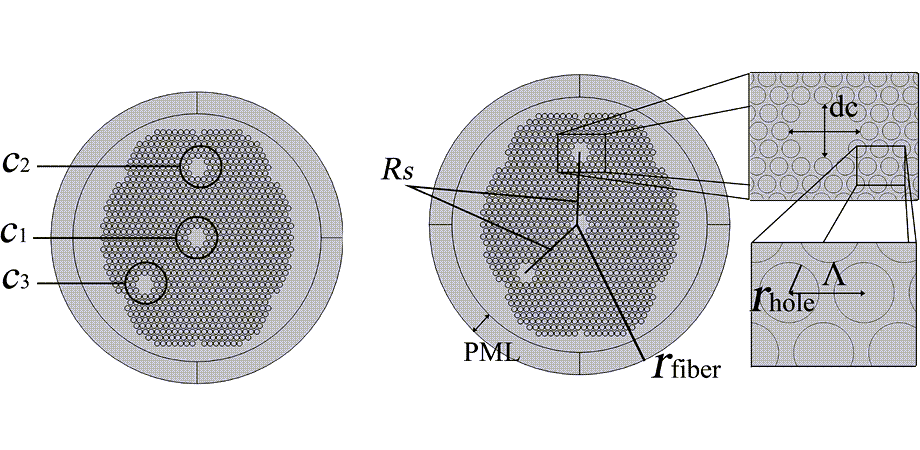

In the proposed optical fiber sensor, there are three fiber cores through which the input light travels. The operating principle of the sensor is based on the concept of what is called “wavelength modulation.” Put simply, when an optical fiber is bent, the structure of the fiber core’s material changes, altering its density. In turn, this modifies the refractive index of the core, and the wavelength of the output light changes depending on how much the fiber was bent. By constructing calibration tables, the magnitude of the spine’s curvature can be estimated based on the difference between the wavelengths of the input and output light in a single core.

But how does this sensor measure the direction of curvature as well as the magnitude? The answer lies in the relative position of the three fiber cores, which create an asymmetric geometry. In other words, each of the fiber cores is bent a little differently when the sensor is placed against the patient’s spine. By comparing the wavelengths of the output light from the two outermost fiber cores, it is possible to calculate the directional component of the bending.

“In general, one of the challenges of designing a sensor is the output relation of the sensor with the value it is sensing. An undesirable situation would be the non-linear relation between the measured item and output. The best condition possible is the linear form,” said Somayeh Makouei, one of the authors of the paper. “One significant advantage of the proposed fiber is that it shows linear results in the output. And also, the length of the curve being measured is one of the constraints in the curvature measurement sensors, especially in optical ones. The proposed fiber does not have any limitations on the length of the curve that is to be measured.”

When compared with another three-core optical fiber sensor reported in a previous study, the new sensor offered a substantially higher sensitivity of about 1.22 picometers per meter in all rotation directions. Moreover, the new sensor was intrinsically more resistant to power fluctuations in the light source—a problem that severely hinders intensity modulation-based sensors.

Overall, the new optical fiber sensor could pave the way for a new method of measuring the curvature of the different sections of the spine. We can hope for further research and design improvements to lead to a convenient and reliable tool for doctors to use.

Read the paper by Saber Moazi Garamaleki and Somayeh Makouei, “Vector bending sensor for measuring spine curvature,” Opt. Eng. 61(9) 097102 (2022) doi 10.1117/1.OE.61.9.097102.

| Enjoy this article? Get similar news in your inbox |

|